EPDM Membrane Roofing Systems is a durable, cost-effective, and energy-efficient choice for roofing solutions for flat or low-slope roofs.

In this post, we’ll delve into the world of EPDM, exploring its composition, benefits, and why it might be the ideal roofing solution for your home.

Let’s get started.

What is EPDM?

EPDM stands for Ethylene Propylene Diene Monomer. It is a type of synthetic rubber commonly used in roofing applications. People use them for low-slope or flat roofs in commercial and residential buildings.

The material derives from oil and natural gas, using ethylene and propylene in its composition. This composition results in a roofing material that stands out for its durability and cost-effectiveness.

Read also: 5 Best roofing shingles brands in the US.

Benefits of the EPDM roofing system

People choose the EPDM (Ethylene Propylene Diene Monomer) roofing system for various reasons, as it offers several advantages that make it a popular choice for commercial and residential applications.

Here are some key benefits why people opt for EPDM roofing:

Low Cost, Long Lifespan

EPDM is considered one of the least expensive low-slope roofing solutions. With a lifespan of up to 50 years, it outshines many alternatives, providing long-term protection for your investment.

Its cost-effectiveness is not only in terms of material cost but also in installation, as it is relatively lightweight and easy to handle.

Read also: Best roofing manufacturers.

Energy Efficiency in Every Climate

Whether battling the heat or the cold, EPDM has you covered. The Carlisle SynTec Systems EPDM Sure-White® reflects sunlight, reducing cooling costs in warmer climates. Conversely, the traditional dark-colored Sure-Seal EPDM helps cut heating costs by absorbing radiant heat in colder regions.

EPDM roofing can contribute to energy efficiency. For example, certain types of EPDM, such as Sure-White®, have reflective surfaces that can help save on cooling costs by reducing the absorption of sunlight.

Easy Installation, Cost Savings

EPDM’s lightweight nature translates into a hassle-free installation process. Its lightweight nature doesn’t add significant weight to the roof structure.

Unlike other low-slope roof systems that may require reinforcing, EPDM’s ease of handling results in lower labor costs and avoids expensive structural upgrades.

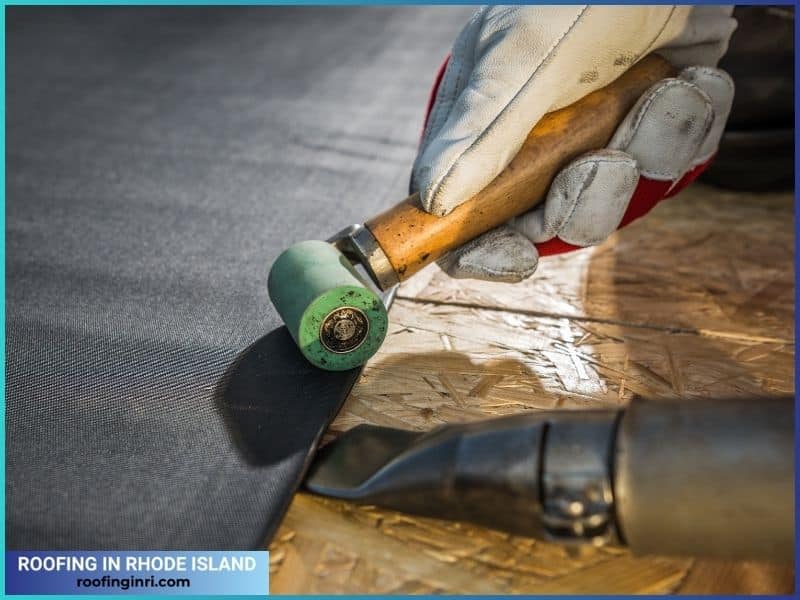

Fully-Adhered Installation for Maximum Protection

We swear by fully adhered EPDM systems. This method ensures the highest uplift resistance and shields your home against water penetration. Our installation process guarantees a secure, watertight seal, giving you peace of mind for years.

Extra Width, Fewer Seams

Choose Carlisle’s Sure-Seal EPDM in rolls up to 10 feet wide and 100 feet long, or opt for Sure-White® with widths up to 20 feet. Fewer seams mean fewer chances for water penetration, enhancing the overall resilience of your roof.

Puncture Resistance and Lasting Flexibility

EPDM comes in various thicknesses, with Carlisle’s Sure-Seal® EPDM standing strong against UV exposure, hail damage, and extreme temperatures. EPDM remains flexible even in low temperatures, making it resistant to cracking or damage. Its flexibility ensures lasting performance even in frigid conditions as low as -40°C.

Durability and Warranty

EPDM roofing systems come with warranties, assuring the property owner regarding the durability and performance of the roofing material.

EPDM can endure up to 50 years when installed and maintained correctly, making it one of the most dimensionally stable and heat-resistant membrane roofing systems available.

Environmental Impact

EPDM is considered more environmentally friendly than other roofing options. Life Cycle Assessment studies have shown that EPDM has a lower global warming potential, lower acid rain impact, and lower contribution to smog.

Do you want an EPDM Roofing System for your home?

Are you exploring the Benefits of an EPDM Roofing System? We invite you to connect with our team for a complimentary assessment tailored to your needs.

Call us at (401) 868-1313 or email to [email protected]

Our experienced professionals offer pressure-free consultations to assist you in making an informed decision about the optimal roofing solution for your home.

What are the disadvantages of EPDM roofing?

While EPDM (Ethylene Propylene Diene Monomer) roofing systems have many advantages, it’s essential to consider some potential drawbacks:

Susceptibility to Punctures

EPDM roofs can be more susceptible to sharp object punctures than other roofing materials.

For example, an EPDM roofing system could be at risk of damage from falling branches during severe weather conditions, such as a heavy storm or hailstorm. Large and sharp branches, or hailstones with significant force, could puncture the EPDM membrane, leading to leaks and needing repairs.

Trimming overhanging branches can reduce the likelihood of punctures and ensure the roofing system’s longevity.

Seam Vulnerability

Seams (joint between two separate sections of roofing material) are potential weak points in any roofing system, and EPDM roofs are no exception. While proper installation is crucial to minimizing seam issues, the adhesive or seam tape used in joining EPDM sheets may degrade over time, leading to potential leaks.

Limited Aesthetic Options

EPDM roofing typically comes in black or white, limiting the aesthetic choices for homeowners. This may be a drawback for those seeking a broader range of colors to match the overall design of their homes.

Not Ideal for Steep Slopes

EPDM is designed for low-slope or flat roofs. I do not recommend it for steep-slope structures. Using EPDM on a steep slope could lead to water pooling and compromised performance.

Environmental Impact of Manufacturing

While EPDM is considered environmentally friendly, manufacturing uses oil and natural gas-derived materials. This can raise concerns about its production’s overall carbon footprint and environmental impact.

Limited Resistance to Certain Chemicals

EPDM may not be suitable for roofs exposed to certain chemicals, oils, or greases, as these substances can potentially degrade the rubber membrane over time.

Weathering over Time

Although EPDM is known for its durability, extended exposure to harsh weather conditions, including extreme UV (ultraviolet) radiation, may lead to weathering over time.

Frequently asked questions

The lifespan of an EPDM roof membrane can vary, but when properly installed and maintained, it can last up to 50 years or more. Factors such as installation quality, climate, and maintenance practices influence the longevity of the EPDM roofing system. Regular inspections and timely repairs extend its lifespan, making it a durable choice for low-slope or flat roofs.

Yes, EPDM roofs are designed to be walked on, but caution should be exercised to avoid damage. Walking on EPDM roofing during installation, maintenance, or inspections is recommended. Use soft-soled shoes and distribute weight evenly to minimize the risk of punctures or tears. Avoid walking on the roof excessively, especially in extreme temperatures, to preserve its integrity. If needed, consult roofing professionals for guidance on proper practices when walking on an EPDM roof.

While EPDM roofs are designed with a slight slope to facilitate water drainage, some water may temporarily sit on the surface after rainfall. EPDM roofing systems are not entirely flat but have a low slope to ensure proper drainage. However, excessive ponding or standing water can occur if there are issues with the roof’s slope or debris obstructs drainage paths. Proper installation and regular maintenance help prevent water ponding and ensure adequate water runoff, preserving the integrity of the EPDM roof.

The cost of an EPDM roofing membrane varies based on factors such as the membrane’s thickness, the roof’s size, and the region. The material cost for EPDM roofing ranges from $0.80 to $2.50 per square foot. Remember that installation costs, which depend on factors like roof complexity and labor rates, are additional. Thicker EPDM membranes and specialized features may incur higher costs.

While installing EPDM roofing in light rain is possible, it’s generally not recommended. Ideally, EPDM installation should occur in dry conditions to ensure proper adhesion and seam sealing.

If rain is anticipated during the installation, precautions such as covering the work area with tarps or halting the installation until the weather clears may be necessary. It’s crucial to follow manufacturer guidelines and consult with roofing professionals to ensure optimal conditions for EPDM installation and avoid potential issues with adhesion and performance.

While EPDM roofing can be installed directly on plywood, it’s essential to follow proper installation procedures to ensure the longevity and performance of the roofing system. Here are some key considerations:

Substrate Preparation: The plywood surface must be clean, dry, and smooth. Any debris, nails, or protrusions should be removed, and the surface should be inspected for structural integrity.

Underlayment: Some EPDM installations may benefit from using an underlayment between the plywood and the EPDM membrane. This can provide additional protection and enhance the roof’s performance.

Adhesive Application: EPDM roofing is often installed using adhesive. The adhesive should be applied evenly, and the EPDM membrane should be carefully laid and pressed into place to ensure proper adhesion.

Seam Sealing: Proper seam sealing is crucial for the effectiveness of the EPDM roof. Whether using adhesive or other seam-sealing methods, following the manufacturer’s guidelines to create watertight seals is essential.

Flashing and Edging: Flashings and edgings, typically made of EPDM or compatible materials, should be installed around roof penetrations, edges, and corners to prevent water infiltration.

Roof Slope: EPDM roofs should have a slight slope to facilitate water drainage. This helps prevent ponding, which can affect the performance and lifespan of the roofing system.

The best thickness of the EPDM (Ethylene Propylene Diene Monomer) roofing membrane depends on factors such as the specific application, climate, and the desired level of durability. EPDM membranes typically come in thicknesses ranging from 45 mil to 90 mil, with 60 mil being a common choice. Here are some general considerations:

45 Mil: Suitable for residential applications with lower foot traffic and milder climates. It offers flexibility and cost-effectiveness.

60 Mil: This is a standard thickness for EPDM roofing and is versatile for residential and commercial use.

90 Mil: Thicker membranes are often chosen for applications requiring additional puncture resistance and durability. This thickness may be preferred for commercial or industrial roofs with higher foot traffic or potential exposure to harsh conditions.

When selecting the thickness of the EPDM membrane, it’s essential to consider factors such as the building’s location, weather patterns, the presence of rooftop equipment or foot traffic, and the specific requirements of the roofing project. Consulting with roofing professionals and adhering to manufacturer recommendations can help determine the most suitable thickness for the intended application.

Under EPDM roofing, using an underlayment or insulation material is common, especially when installing the membrane over a plywood or OSB (oriented strand board) substrate. It prevents damage from any imperfections or roughness on the substrate.

Conclusion

EPDM Membrane Roofing Systems emerge as a versatile, cost-efficient, and environmentally friendly choice in roofing solutions. EPDM promises longevity, energy efficiency, and peace of mind from inception to installation. If you’re contemplating a roofing upgrade, consider the enduring benefits of EPDM – a roofing superhero for every home.

EPDM has been a popular choice for roofing applications for nearly six decades due to its durability, cost-effectiveness, and ease of installation.